CNC Machining in Wooden Cutting Board Production: Precision at Its Finest

CNC Machining in Wooden Cutting Board Production: Precision at Its Finest

The Importance of CNC Machining in Modern Woodworking

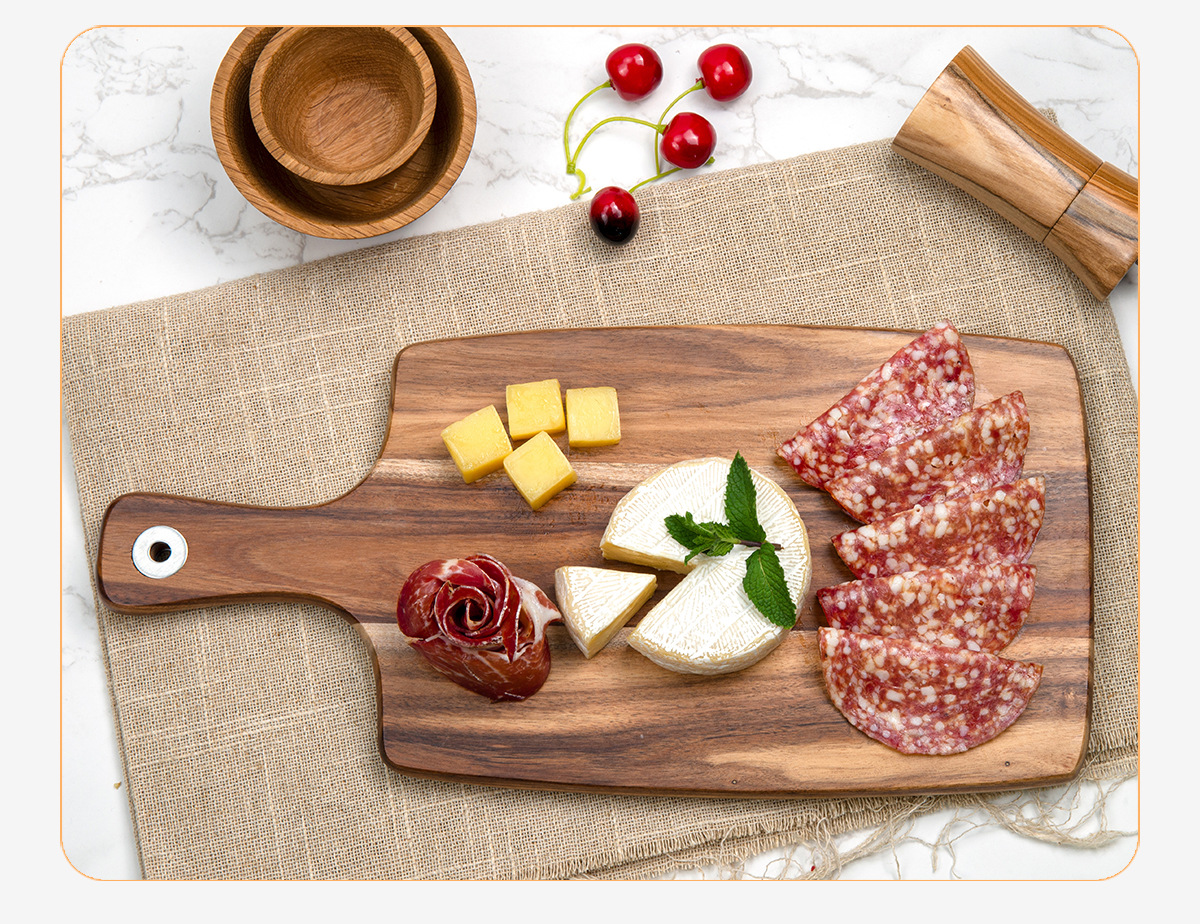

The world of kitchenware manufacturing has undergone a remarkable transformation, with wooden cutting boards becoming more than just practical tools—they are now symbols of culinary craftsmanship and design sophistication. One of the critical steps that elevates the quality and consistency of wooden boards is CNC machining, often referred to in China as “电脑锣机加工” (computer gong machine processing). This article takes you behind the scenes of how advanced CNC technology is revolutionizing the production process of high-quality wooden cutting boards.

How CNC Technology Delivers Consistency

CNC (Computer Numerical Control) machining is an automated process where pre-programmed software dictates the movement of machinery and tools. In cutting board manufacturing, this means wood can be shaped, engraved, and finished with pinpoint accuracy. Whether crafting a Reversible wood Cutting Board or intricate designs for an engraved cheese board, CNC machining ensures every detail meets exacting standards.

Preparing the Raw Materials

It all starts with premium wood—selected for its durability, grain, and natural beauty. Common choices include maple, walnut, cherry, and beech, each providing unique qualities. The timber is seasoned, kiln-dried, and cut to rough dimensions. These planks undergo initial planing and thicknessing, creating a uniform base for the next stages.

Digital Design: From Concept to Blueprint

The heart of CNC machining is the digital blueprint. Engineers and designers create detailed CAD (Computer-Aided Design) files that translate design concepts into machining instructions. For a wood charcuterie board or a round pizza tray, the desired shape, engraving, and functional details are all embedded in these digital plans.

Machining Process: Shaping and Engraving with Precision

With the design set, the CNC machine takes over. High-speed rotating bits sculpt the wood, cutting it into precise shapes with smooth, rounded edges. For reversible cutting boards, the CNC ensures each side is perfectly flat and symmetrical. Customization, such as laser-engraved logos or patterns, is effortlessly handled—whether it’s adding a name to an engraved cheese board or a signature logo on an oval cutting board.

During this phase, the CNC machine also drills juice grooves, finger grips, and handles, optimizing each piece for both aesthetics and usability. Round pizza trays require precise circular cutting and gentle beveling—tasks that CNC handles with ease and repeatability.

Inspection and Quality Control

After machining, each board is meticulously checked for dimensional accuracy. Tolerances are incredibly tight—often less than a millimeter. Boards that do not meet strict requirements are set aside for reworking or recycling. This focus on precision guarantees that every product, whether a simple oval cutting board or a complex multi-functional tray, meets the expectations of discerning B2B clients.

Finishing Touches by Skilled Hands

Machined boards still need that human touch. Skilled workers hand-sand the surfaces, ensuring all edges are smooth and comfortable to the touch. Attention to detail is critical—no sharp corners or uneven textures. After sanding, boards may be dipped or wiped with food-safe mineral oil, enhancing their natural luster and providing protection against moisture.

Branding, Packaging, and Customization

For businesses seeking differentiation, CNC machines can engrave custom logos, text, or artwork onto the surface. This capability is especially popular for engraved cheese boards destined for corporate gifting or retail. Once finished, each board is inspected, polished, and carefully packaged, ready for global shipment.

Sustainability and Resource Efficiency

CNC machining is not only about precision but also about resource efficiency. The ability to maximize yield from every plank reduces waste. Many factories utilize leftover wood chips for secondary products or biofuel, contributing to sustainable manufacturing.

Creative Freedom for Brands and Designers

The flexibility of CNC machining enables manufacturers to push creative boundaries. From round pizza trays with integrated handles to reversible wood cutting boards with juice grooves on one side and a flat surface on the other, the possibilities are endless. Custom shapes, personalized engravings, and unique finishes have made wooden cutting boards an expressive canvas for both brands and chefs.

Meeting the Needs of B2B Clients

Businesses in the hospitality, food service, and retail industries demand consistency, quality, and the ability to customize products. CNC machining delivers all three—ensuring that every batch of wood charcuterie boards, round pizza trays, or engraved cheese boards is identical in size, shape, and finish.

Why Partner with Us for Your Wooden Cutting Board Needs?

We combine tradition with innovation. Our CNC machining process guarantees you receive only the best—products that meet your exact specifications and uphold the highest standards of craftsmanship.

Contact us for partnership, wholesale inquiries, or custom orders:

Email: info@justwoodencuttingboard.com

WhatsApp: +86 183 1248 3616

Stay Connected for More Innovations

Follow us on LinkedIn, Facebook, Instagram,Youtube to get the latest updates, industry insights, and product launches.

Take your product line or business to the next level with customized, high-quality wooden boards—made with precision, designed for excellence.

Yangjiang Cuthaven Kitchenware Co.,Ltd

Yangjiang Cuthaven Kitchenware Co.,Ltd.

specializes in the production and export of high-quality metal and wooden kitchenware. With over 16 years of experience in the industry, we have established ourselves as a trusted partner for businesses worldwide.